Challenge

Goose Island Brewery has become known for its unique barrel-aged brews including the popular Matilda, Sofie, and Juliet. With the steady increase in demand from the marketplace, Goose Island recognized that they needed to increase their production capacity for this type of brew. They ultimately selected Kroeschell to perform the multi-million dollar process line upgrade and expansion.

Solution

During the 23-day shutdown of the facility, Kroeschell dedicated over 5,000 labor hours to complete the upgrade. Kroeschell self-performed all pipe fitting, electrical and control work and took on the general contracting role to manage all other trades.

The project included the demolition of existing:

- Process equipment and piping

- Steam piping

- Condensate piping

- Electrical panels

- Electrical conduit and wire

- Concrete floors in two areas

This project included the installation of new:

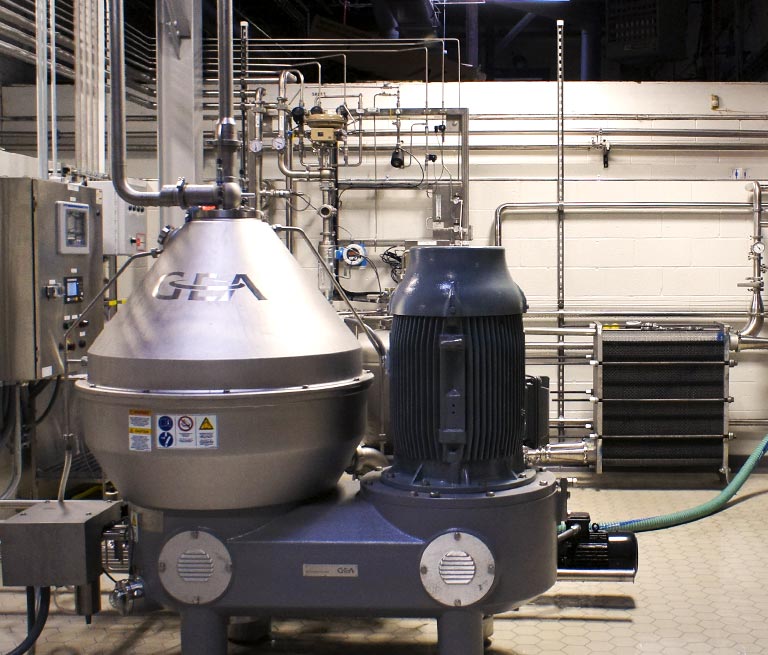

- Owner furnished process equipment; mash press filter, centrifugal separator, hot liquor tank, cyclone separator, hammer mill.

- 20 ton make-up air unit for a process area

- 20 ton condensing unit

- Trench drain for a process area

- Stainless steel process piping

- Steam and condensate piping

- Rebar reinforced concrete floors in two areas

- Structural steel support platform and stairway

- Electrical panels/switchgear, conduit and wire

The installation of the new mash filter posed a challenge for Kroeschell as it was the first time the team had ever installed this type of equipment. Furthermore, the mash filter arrived with several components that were supplied by different manufacturers. It became clear that because the system was not pre-assembled before delivery that many field modifications were necessary. Under a tight deadline, Kroeschell worked closely with Goose Island and the manufacturer’s technical field personnel to make major modifications to get the system to work correctly.

Results

While Kroeschell was met with challenges during the installation of equipment, the project remained on schedule and was ultimately completed on-time. Goose Island restarted their brewing production as planned with new equipment capable of producing 500 additional barrels per week.