About this project

For over 25 years, Nicor Gas has operated their central utility plant (CUP) with co-generators, whereby using natural gas to run generators to make electricity that powers the entire facility while recovering waste heat for HVAC use.

Challenge

Due to recent EPA air quality regulations, coupled with a system that had reached the end of its lifecycle, Nicor decided to phase out cogen and modernize their CUP. Kroeschell was selected to upgrade their existing cogen equipment with new standby generators; however, due to the age of the remaining mechanical equipment in the CUP and the outdated BAS system, Nicor decided to perform a major upgrade on all heating and cooling equipment and associated components.

Solution

The year-long multi-million dollar design-assist project included the installation of:

Mechanical Equipment:

- Three (3) 5000 MBH Bryan gas-fired boilers

- Two (2) 400 ton Daikin water cooled chillers

- Three (3) 500 ton cooling towers

- One (1) 118 ton Multistack chiller for computer room cooling

- Four (4) Liebert computer room AC units (ranging from 8-22 tons)

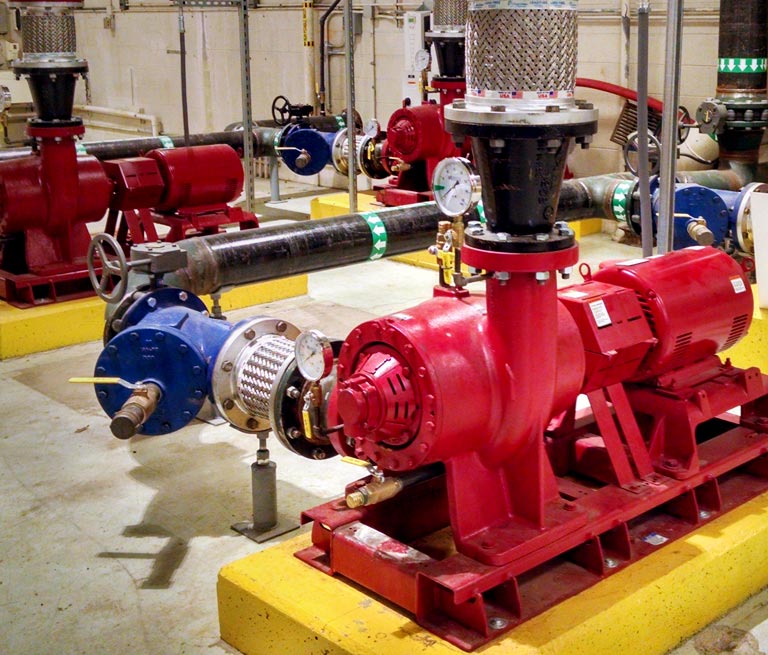

- 11 verticle split case pumps; seven (7) end suction pumps; two (2) horizontal split case pumps; six (6) inline pumps

Electrical and BAS Equipment:

- Three (3) 600kW bi-fuel standby generators

- One (1) 2000A generator switchgear

- One (1) 4000A automatic transfer switch (ATS)

- Alerton BAS control system

- Front-end graphics system

- Multiple VFDs for chillers, boilers, pumps, computer room chiller

Kroeschell managed the highly complex project while minimizing equipment shut down so as not to jeopardize the functioning of the office building. This allowed the Nicor facility to continue business as normal throughout the entirety of the project. Additionally, Kroeschell handled all major scopes of work including electrical, pipefitting, controls and mechanical, and took on the General Contractor role to manage all other trades.

Results

Though this was a design-assist project, Kroeschell was able to use its engineering review skills to solve unexpected problems, minimize disruptions to the schedule and offer suggestions to save money and improve the functionality of the CUP.